PP Chamber Lim Phaj

Kev piav qhia

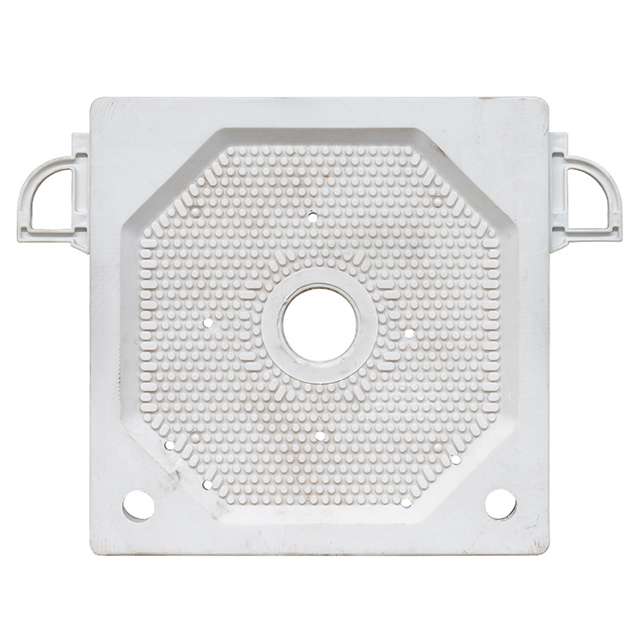

Lim phaj yog qhov tseem ceeb ntawm kev lim xovxwm. Nws tau siv los txhawb nqa cov lim thiab khaws cov khoom qab zib lim dej hnyav. Qhov zoo tshaj ntawm lub lim phaj (tshwj xeeb tshaj yog lub tiaj tiaj thiab precision ntawm lub lim phaj) yog cuam tshuam ncaj qha rau cov nyhuv lim thiab pabcuam lub neej.

Cov khoom sib txawv, cov qauv sib txawv thiab kev zoo yuav cuam tshuam rau tag nrho cov tshuab kev ua tau zoo ncaj qha. Nws pub zaub mov qhov, lim cov ntsiab lus faib (lim channel) thiab lim pom kev tso tawm raws cov qauv sib txawv raws li cov khoom sib txawv.

| Cov Khoom Siv Ntawm Cov Phiaj Lij | Pp phaj, membrane phaj, cam khwb cia hlau lim phaj, stainless hlau tshuab phaj. |

| Daim ntawv ntawm pub mis | Nruab nruab nrab, ces kaum kev noj mov, sab saud nruab nrab pub, thiab lwm yam. |

| Daim ntawv ntawm filtrate rho tawm | Pom ntws, unseen ntws. |

| Hom Phaj | Phaj-ncej lim phaj, chav lim lim phaj, membrane lim phaj, decessed lim phaj, recessed lim phaj. |

✧ Khoom nta

Polypropylene (PP), tseem hu ua cov molecular hnyav polypropylene. Cov ntaub ntawv no tau ua tau zoo heev rau ntau cov acids thiab alkali, suav nrog cov muaj zog acid hydrofluoric acid. Nws muaj zog nruj thiab rigidity, txhim kho lub compression sealting kev ua haujlwm. Haum rau lim presses.

1. Kev hloov kho thiab txhawb nqa polypropylene nrog cov mis tshwj xeeb, pwm hauv ib qho mus.

2. Tshwj xeeb cnc khoom siv, nrog lub tiaj tiaj thiab kev ua tau zoo sib luag.

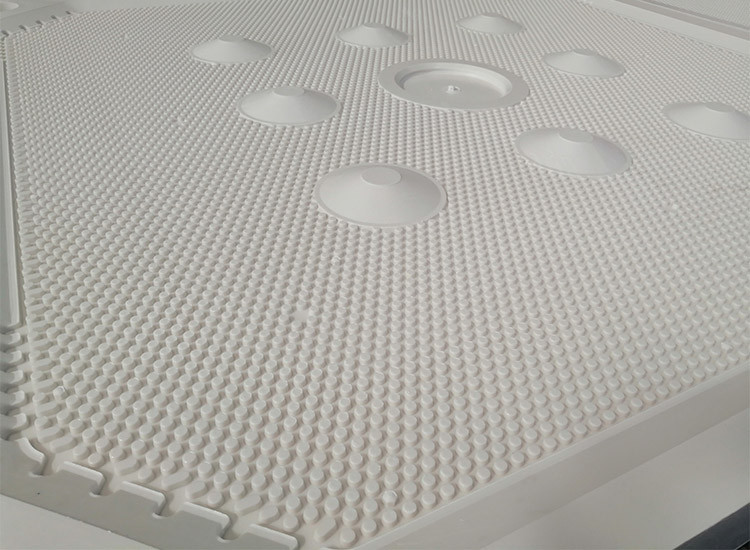

3. Lub taub lim cov qauv tau txais cov qauv sib txawv ntawm tus qauv hla kev sib xyaw ua ke hauv lub plum blossom zoo li ntawm cov kev lim dej tiv thaiv cov khoom;

4. Qhov kev nrawm nrawm nrawm nrawm, tus qauv tsim tawm channel filtrate yog qhov tsim nyog, thiab cov txiaj ntsig kev lag luam ntawm cov lim xovxwm.

5. Kev txhawb nqa polypropylene lim phaj kuj muaj qhov zoo xws li lub zog siab, acid, alkali tsis kam, cov kua qaub, thiab lom.

✧ Daim ntawv thov kev lag luam

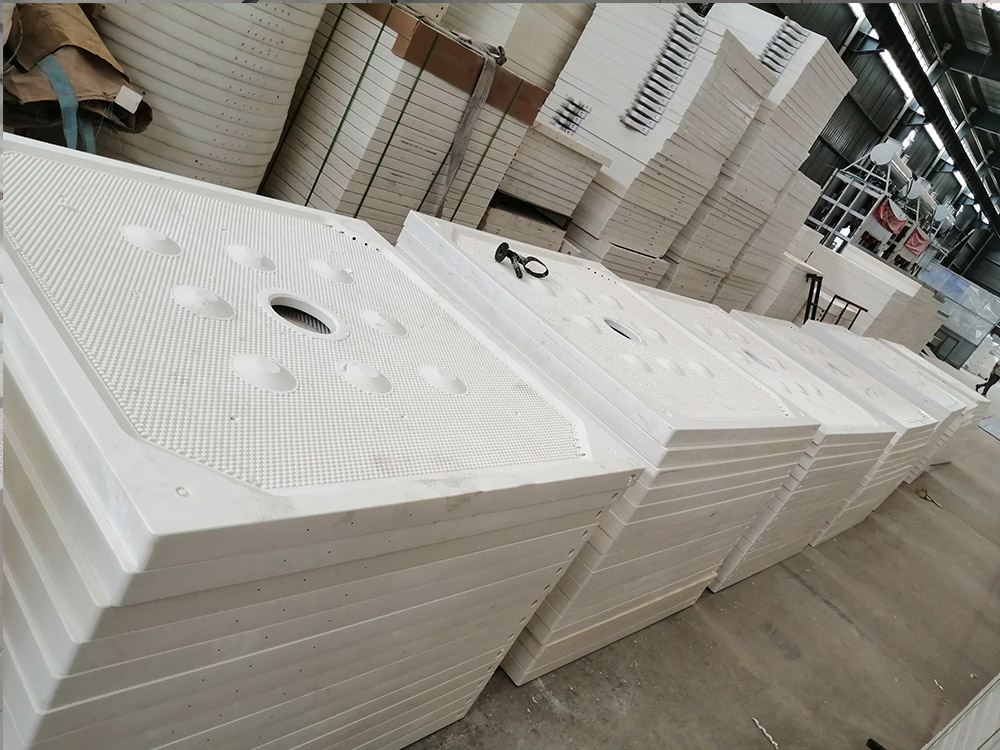

Lub tshuab lim muaj cov khoom siv tau muaj zog thiab cov khoom lag luam zoo, cov khoom lag luam muaj teeb meem, kev tiv thaiv khoom, kev tiv thaiv kev lag luam hauv ntiaj teb, thiab lwm yam.

✧ Lim Phaj Parameter

| Qauv (hli) | PP Camer | Diaphragm | Kaw lawm | Stainless hlau | Nrum Hlau | PP thav duab thiab phaj | Vij |

| 250 × 250 | Lwm | ||||||

| 380 × 380 | Lwm | Lwm | Lwm | Lwm | |||

| 500 × 500 | Lwm | Lwm | Lwm | Lwm | Lwm | ||

| 630 × 630 | Lwm | Lwm | Lwm | Lwm | Lwm | Lwm | Lwm |

| 700 × 700 | Lwm | Lwm | Lwm | Lwm | Lwm | Lwm | |

| 800 × 800 | Lwm | Lwm | Lwm | Lwm | Lwm | Lwm | Lwm |

| 870 × 870 | Lwm | Lwm | Lwm | Lwm | Lwm | Lwm | |

| 900 × 900 | Lwm | Lwm | Lwm | Lwm | Lwm | Lwm | |

| 1000 × 1000 | Lwm | Lwm | Lwm | Lwm | Lwm | Lwm | Lwm |

| 1250 × 1250 | Lwm | Lwm | Lwm | Lwm | Lwm | Lwm | |

| 1500 × 1500 | Lwm | Lwm | Lwm | Lwm | |||

| 2000 × 2000 | Lwm | Lwm | Lwm | ||||

| Qho so | 0-100 ℃ | 0-100 ℃ | 0-100 ℃ | 0-200 ℃ | 0-200 ℃ | 0-80 ℃ | 0-100 ℃ |

| Nyem | 0.6-1.6MPA | 0-1.6MPA | 0-1.6MPA | 0-1.6MPA | 0-1.0MPA | 0-0.6MPA | 0-2.5MPA |

| Lim Phaj Parameter Daim Ntawv | |||||||

| Qauv (hli) | PP Camer | Diaphragm | Kaw lawm | Stainlesshlau | Nrum Hlau | Pp ncejThiab Phaj | Vij |

| 250 × 250 | Lwm | ||||||

| 380 × 380 | Lwm | Lwm | Lwm | Lwm | |||

| 500 × 500 | Lwm | Lwm | Lwm | Lwm | Lwm | ||

| 630 × 630 | Lwm | Lwm | Lwm | Lwm | Lwm | Lwm | Lwm |

| 700 × 700 | Lwm | Lwm | Lwm | Lwm | Lwm | Lwm | |

| 800 × 800 | Lwm | Lwm | Lwm | Lwm | Lwm | Lwm | Lwm |

| 870 × 870 | Lwm | Lwm | Lwm | Lwm | Lwm | Lwm | |

| 900 × 900 | Lwm | Lwm | Lwm | Lwm | Lwm | Lwm | |

| 1000 × 1000 | Lwm | Lwm | Lwm | Lwm | Lwm | Lwm | Lwm |

| 1250 × 1250 | Lwm | Lwm | Lwm | Lwm | Lwm | Lwm | |

| 1500 × 1500 | Lwm | Lwm | Lwm | Lwm | |||

| 2000 × 2000 | Lwm | Lwm | Lwm | ||||

| Qho so | 0-100 ℃ | 0-100 ℃ | 0-100 ℃ | 0-200 ℃ | 0-200 ℃ | 0-80 ℃ | 0-100 ℃ |

| Nyem | 0.6-1.6MPA | 0-1.6MPA | 0-1.6MPA | 0-1.6MPA | 0-1.0MPA | 0-0.6MPA | 0-2.5MPA |