Khoom Taw Qhia:

Lub hnab limbelongs rau lub raj xa dej ntxhib lim series thiab tseem tuaj yeem siv rau kev pom cov khoom loj hauv cov pa roj lossis lwm yam xov xwm. Nruab rau ntawm lub raj xa dej tuaj yeem tshem tawm cov khoom tsis zoo hauv cov kua dej, ua kom cov tshuab thiab cov khoom siv (xws li compressors, twj tso kua mis, thiab lwm yam) thiab cov cuab yeej ua haujlwm thiab ua haujlwm zoo li qub, txhawm rau txhim kho cov txheej txheem thiab xyuas kom muaj kev nyab xeeb.

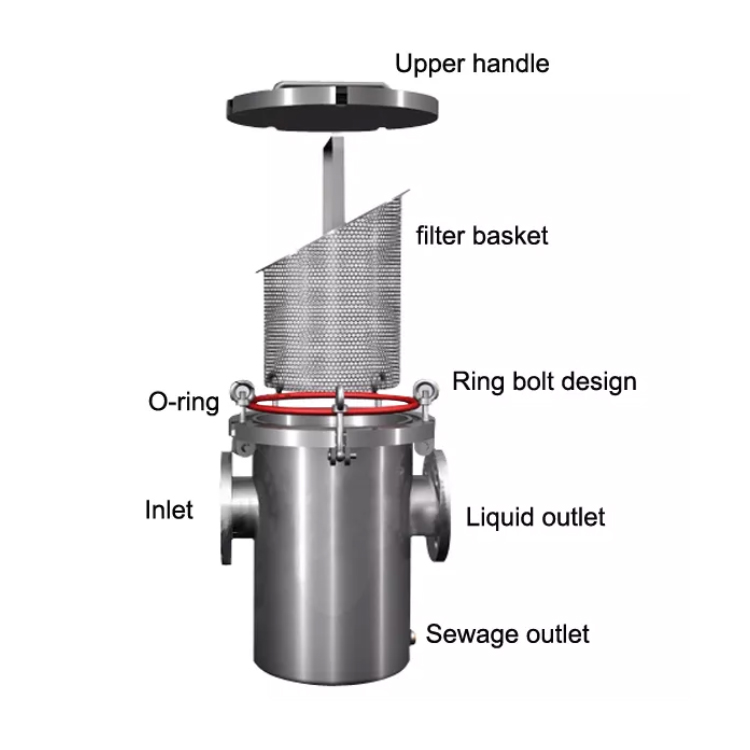

Cov khoom muaj pes tsawg leeg:

Pob tawb lim cartridge, mesh pob tawb, flange npog, flange, seals

Khoom siv: carbon steel, SS304, SS316

Lub nplhaib foob: PTFE, NBR. (Cov dej ntsev lim sealing nplhaib siv fluorine roj hmab, pob PTFE)

Inlet thiab qhov hluav taws xob: flange, puab hlau, sab nrauv, ceev tso tawm.

Lub hau: ntsia liaj qhov rooj, ceev tso ntsia liaj qhov rooj

Mesh pob tawb: perforated mesh, ib txheej mesh, composite mesh

Adaim ntawv thov:

Kev lag luam tshuaj:Hauv kev tsim tshuaj lom neeg, nws yog siv los lim ntau yam tshuaj raw cov ntaub ntawv, cov khoom nruab nrab, thiab cov khoom, tshem tawm impurities, catalyst hais, thiab lwm yam, txhawm rau txhim kho cov purity thiab zoo ntawm cov khoom. Piv txwv li, nyob rau hauv cov tshuaj tua kab ntau lawm, lub ncua kev kawm ntawv tom qab pom cov tshuaj tiv thaiv yog siv los tshem tawm unreacted raw khoom hais thiab impurities, uas ua rau cov tshuaj tua kab ntshiab.

Pharmaceutical kev lag luam:siv rau kev lim dej hauv cov txheej txheem tshuaj, tshem tawm cov kab mob, cov khoom thiab lwm yam impurities los xyuas kom meej qhov zoo thiab kev nyab xeeb ntawm cov tshuaj. Piv txwv li, hauv kev tsim tshuaj tua kab mob, cov fermentation broth yog lim kom tshem tawm cov kab mob, impurities, thiab lwm yam, muab cov khoom tsim nyog rau kev ua kom huv thiab ua kom zoo dua tom qab.

Khoom noj khoom haus thiab dej haus kev lag luam:siv rau lim kua txiv hmab txiv ntoo, mis nyuj, npias, roj noj thiab lwm yam khoom noj thiab dej haus, tshem tawm impurities xws li txiv hmab txiv ntoo pulp, sediment, microorganisms, thiab lwm yam, thiab txhim kho cov khoom transparency thiab saj. Piv txwv li, hauv cov kua txiv hmab txiv ntoo, cov kua txiv hmab txiv ntoo yog lim thiab nias kom tshem tawm cov tawv nqaij thiab fiber ntau impurities, ua rau cov kua txiv hmab txiv ntoo ntshiab.

Kev kho dej kev lag luam:siv rau kev kho cov dej khib nyiab thiab cov dej phwj hauv tsev, tshem tawm cov khib nyiab, colloids, organic teeb meem thiab lwm yam impurities hauv dej, txo cov turbidity thiab chromaticity ntawm dej, thiab txhim kho cov dej zoo. Piv txwv li, hauv cov chaw kho dej phwj tuaj, lub hnab lim tau siv los lim cov dej phwj tuaj ua ntej, tshem tawm cov khoom zoo thiab cov impurities los ntawm cov dej, muab cov xwm txheej rau kev kho mob sib sib zog nqus.

Electroplating kev lag luam:siv rau kev lim dej electroplating, tshem tawm cov hlau impurities, plua plav, thiab lwm yam., ua kom huv si ntawm cov tshuaj electroplating, txhim kho electroplating zoo, thiab tiv thaiv impurities los ntawm kev tsim qhov tsis xws luag ntawm qhov chaw plated.

Post lub sij hawm: Apr-03-2025